Industrial scales: precision weighing for efficiency and accuracy

Industrial scales are specialized weighing systems designed to measure heavy loads and bulk materials with high accuracy. Used across manufacturing, logistics, agriculture, and laboratory settings, these scales ensure precise weight measurements for quality control, inventory management, and regulatory compliance. Their robust construction and advanced features make them a dependable choice for high-capacity and demanding environments.

Types of industrial scales

Different types of industrial scales cater to specific applications:

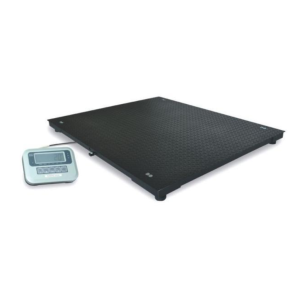

- Floor scales – Large, heavy-duty platforms designed for weighing pallets, drums, and bulk materials in warehouses and production facilities.

- Bench scales – Compact and versatile, suitable for small to mid-sized weighing tasks in packaging, food processing, and retail environments.

- Crane scales – Suspended weighing systems for measuring heavy loads in shipping, construction, and metalworking industries.

- Weighing pallet trucks – Integrated scale systems in pallet jacks, enabling weight measurement while transporting goods.

- Counting scales – Designed for precision counting of small components or parts, commonly used in inventory management.

Why choose industrial scales over alternative weighing methods?

Compared to manual estimation or standard consumer scales, industrial scales provide several advantages:

- High precision – Ensures accurate measurements even for heavy loads, reducing errors in shipping, production, and transactions.

- Durability – Built to withstand industrial conditions, including exposure to dust, moisture, and heavy usage.

- Efficiency in operations – Speeds up weighing and tracking processes, enhancing workflow and productivity.

- Compliance with industry regulations – Many industrial applications require precise weight data for legal, safety, and quality standards.

Key factors to consider when selecting an industrial scale

Choosing the right industrial scale depends on several critical aspects:

- Weighing capacity – Match the scale’s weight limit to the heaviest loads it will measure.

- Platform size and design – Ensure the scale dimensions fit the materials or products being weighed.

- Accuracy and readability – Consider the scale’s precision level, especially for applications requiring fine measurements.

- Environmental factors – Look for features such as waterproof, dust-resistant, or explosion-proof designs if operating in challenging conditions.

- Connectivity and integration – Some models offer digital interfaces, data logging, and connectivity to ERP or warehouse management systems.

Industrial scales play a crucial role in optimizing weighing processes for businesses across multiple sectors. Whether used for shipping, production monitoring, or laboratory analysis, these scales enhance efficiency, accuracy, and compliance, making them a vital component of industrial operations.